Epson GENESTA inks are Pigment formulations, and are ECO PASSPORT certified to meet globally recognised standards for environmentally friendly textile printing. Our Acid ink is also bluesign® approved, and our Reactive and Pigment inks are GOTS approved by ECOCERT.

The ML-8000 boasts a typical print speed of 162 square metres per hour (2-pass printing at 600 x 600 dpi). Epson precision dot technologies include Microweave and lookup table (LUT) technologies that reduce banding and graininess, and advanced new Multi-Layer Halftone Technology (MLHT) that randomises the halftone dot pattern to reduce image degradation caused by dot misalignment. Dynamic Alignment Stabiliser (DAS) technology also ensures stable print quality by controlling waveforms on each printhead chip for higher dot placement accuracy and more uniform dot density on each pass.

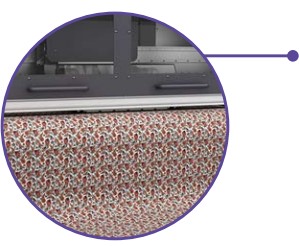

Stable operation and unprecedented usability are realised by advanced cleaning mechanisms and automated adjustment functions. A fluff blower system removes fluff from the fabric surface before it enters the printing area, and an ink mist extraction system helps reduce nozzle clogging problems. In the event a nozzle does become clogged, Nozzle Verification Technology (NVT) detects missing dots and adjusts ink delivery to maintain image quality and reduce printing errors. Auto nozzle cleaning by fabric wiper reduces daily manual maintenance work. With high-accuracy head alignment technology and automatic calibration by the built-in RGB camera, printhead replacement and calibration can be completed easily. In addition, the Epson Remote Monitoring System reduces downtime and service calls by allowing quick response to potential problems.

Ease of use is enhanced by a 9-inch LCD touch panel that displays current printer status, operating instructions, and regular maintenance procedures, and by hot-swappable, dual 10-litre or 3-litre high-capacity ink cartridges that allow uninterrupted production.

Please complete the form below and click send to send a product enquiry.